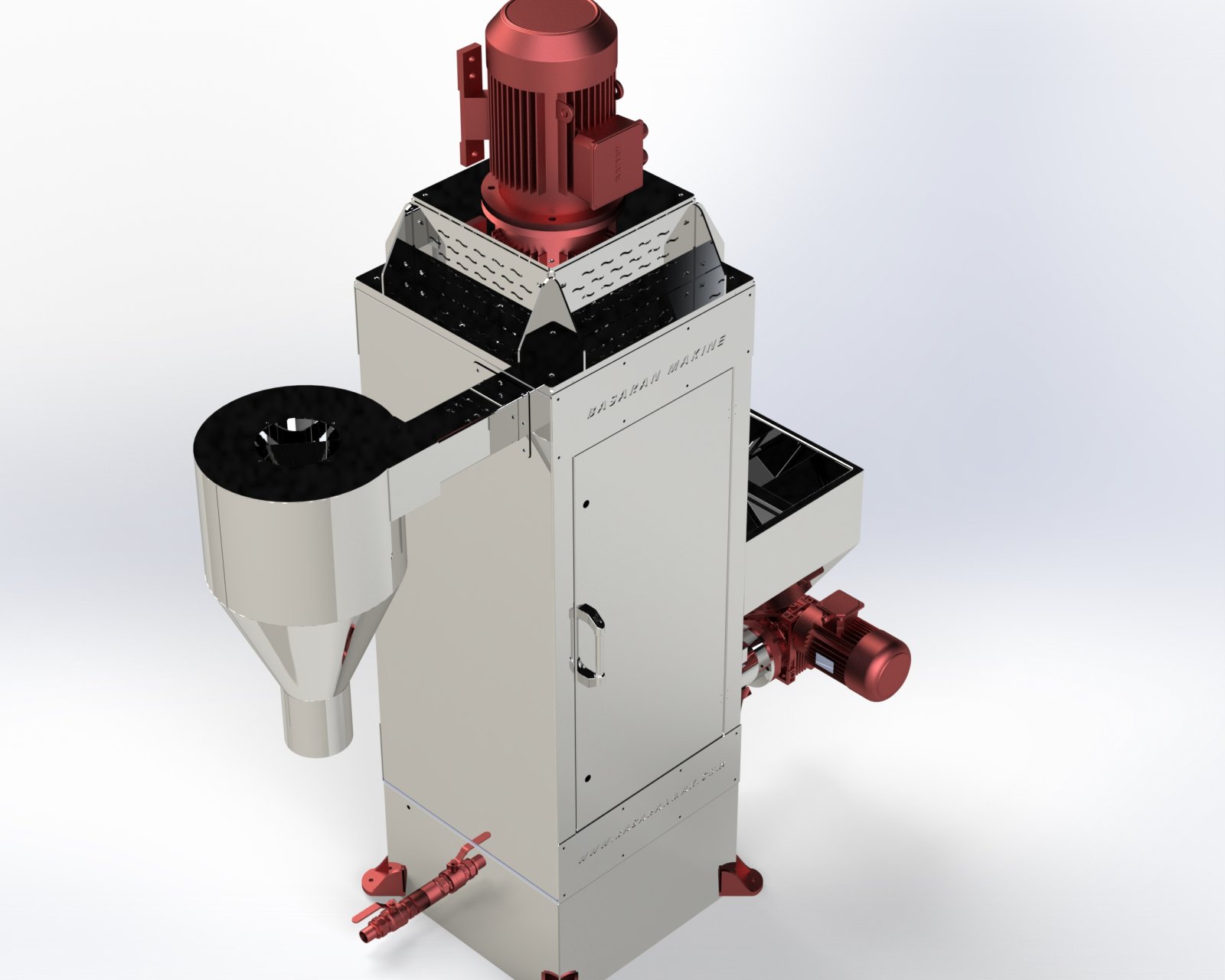

Vertical Centrifuge

Centrifuges are devices designed to separate and dry substances of different weights by rotating at high speed in boilers of different sizes depending on gravity. Thanks to this movement, the particles in suspension rotate and separate with a revolution greater than the acceleration of gravity. In vertical centrifuge devices, plastics gain acceleration according to their density and size. Thus, wastes in different forms are dehumidified and dried.

Vertical centrifuge machines are washing and drying machines used for the recycling of plastic waste. Vertical centrifuge machines wash plastic wastes under water at high speeds and create a deep hygiene on the residues with its superior friction power thanks to the rotor chamber. Improved rotor designs in these devices give excellent results on film or burrs. Thanks to the rotor and the access area in the sieve section of the device, cleaning and maintenance operations and their duration can be completed within minutes. On the other hand, turbo washing centrifuges are produced from carbon steel and stainless steel.

Dynamic centrifuge machines are used in the dewatering process of hard burr plastics from wastes at high speeds. These devices, which have special rotor designs, have the capacity to almost eliminate the moisture level in burr materials. Again, since the sieve and rotor sections are located in the easy access area, it is very easy to clean and maintain. Thanks to the inverter system feeding screw in the device, it is not affected by the capacity fluctuation during dewatering. The device is made of stainless steel material.