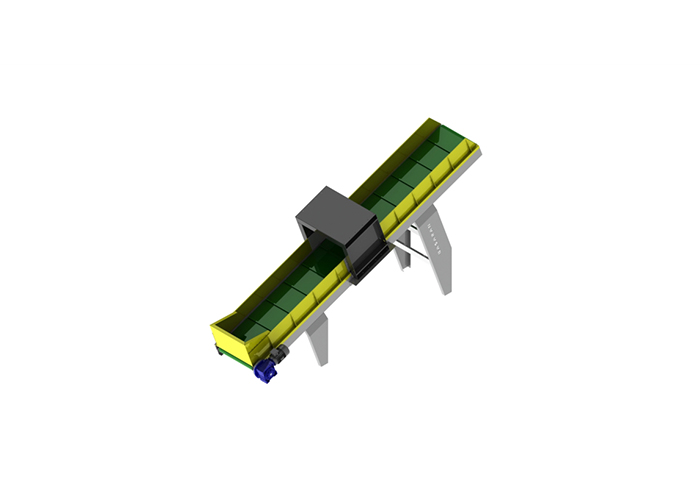

Conveyor Belt

The recycling journey begins with the dumping of waste into the system by garbage trucks, and this starting point starts with the conveyor belt system and is completed with stages such as sorting - sorting, washing, drying, pressing, storage. The main tasks and features of conveyors are to sort and select the waste transport content. Conveyors, which can also be used in different areas of use, can show the success of distinguishing vibratory - magnetic metal or metal derivatives.

Thanks to the technologies developed in recent years, almost all products that have expired can be recycled in the recycling area. While these materials, which are reprocessed and turned into raw materials, do not consume nature in an ecological sense, they do not tire the companies economically. Recycling processes require a range of machinery equipment, such as recycling line systems.

In this way, there are those that have the ability to distinguish waste. In this way, recycling wastes are separated. Conveyors are divided into groups such as acetal belt, idler roller, elevator conveyors, conveyor automation, miniature conveyors, transit conveyors, modular belt conveyors, special conveyors, pvc belt conveyors, drive roller conveyors, dynamic rack systems. Paper, plastic, glass, metal etc. flowing through conveyors. You can separate any type of material.

By means of the conveyor belt, products or wastes can be transferred from one place to different points in a cost-free way and at the same time they can be clearly controlled. Especially the conveyors, which carry out the transmission of large wastes in minutes, save time and also prevent waste in labor.