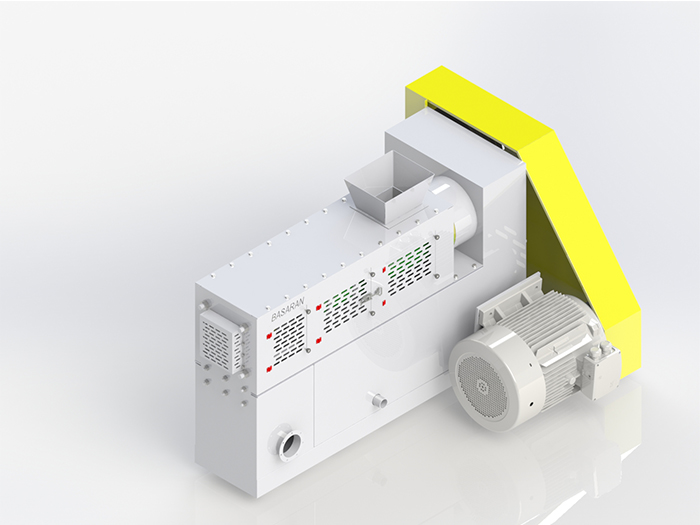

Plastic Crimping Machine

Plastic squeezing machine is supported by high torque extruder type reducers, gas metal strong chassis and strong service steels. On the other hand, squeezing processes can also be supported by argomel machines upon request. Argomel machines are used in the processes of drying and densifying moist plastics thanks to the frictional heat generated by using high-speed rotating blades.

Argomel dryers have different blade sizes according to the tub diameter. Again, the type and capacity of the plastic are taken into account in the selection of the argomel machine.

Plastic waste materials, which are transferred to the washing tubs by passing through the crushing machines in the recycling lines, are transferred to the squeezing machines and go through the dewatering process by means of mechanical squeezing methods. Thus, they are made ready for drying.

Here, the humidity rate is reduced between 4 and 8%, depending on the type and thickness of the plastic. Developed with superior technologies, these devices are not affected by capacity fluctuations thanks to their superior screw designs. Considering the ease of use, capacity, efficiency and cost of the plastic squeezing machine, it is quite functional and economical in dewatering compared to the hot air centrifuge system.

Boiler bodies of Argomel machines are produced from stainless steel and carbon steel. Since the devices are included in the developed bedding system, maintenance operations can be carried out easily. Turbo washing centrifuges and dynamic drying centrifuges are also used for plastic squeezing machines.

Plastics washed under high-speed water in turbo washing systems are thoroughly cleaned thanks to the friction provided by the rotor areas, and the cleaning period is completed in minimum time. Dynamic drying systems are used for dewatering hard burr plastics at high speeds. Thanks to the special rotor sections, the moisture content of the material can be reduced by 1% so that it is almost never left.